Industrial Application Group

Research Overview

In this study, we propose a cable wiring method using a robot arm that leverages deep learning and vision-based models, addressing key challenges in the automation of cable routing. By employing deep learning models, the system simultaneously processes visual information and joint angles, enabling real-time recognition and adaptive motion path planning. Visual data is captured by a RealSense camera, allowing the robot arm to accurately interpret the working environment and extract key features relevant to cable manipulation.

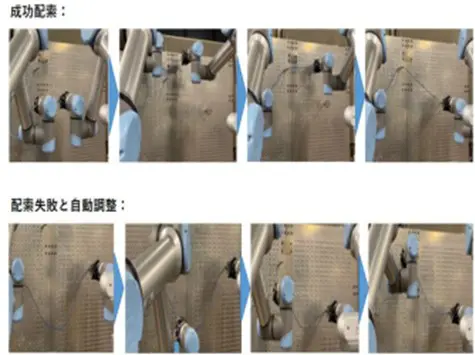

Through multimodal data integration, deep learning enables the fusion of sensor information, making it possible to predict motions and dynamically adjust paths, thereby addressing issues related to cable deformation during wiring. Experimental evaluations across diverse scenarios—such as varying cable quantities, colors, and operation speeds—demonstrate the model’s potential to achieve high prediction accuracy and robustness even in complex environments.

The proposed approach aims to significantly improve both wiring efficiency and stability, while also incorporating fault detection and self-repair capabilities. This study contributes to the fields of industrial automation and flexible material handling, with future directions focusing on further optimization of model performance, expansion of experimental conditions, and broadening of applications to automated assembly systems.